When Accuracy Matters

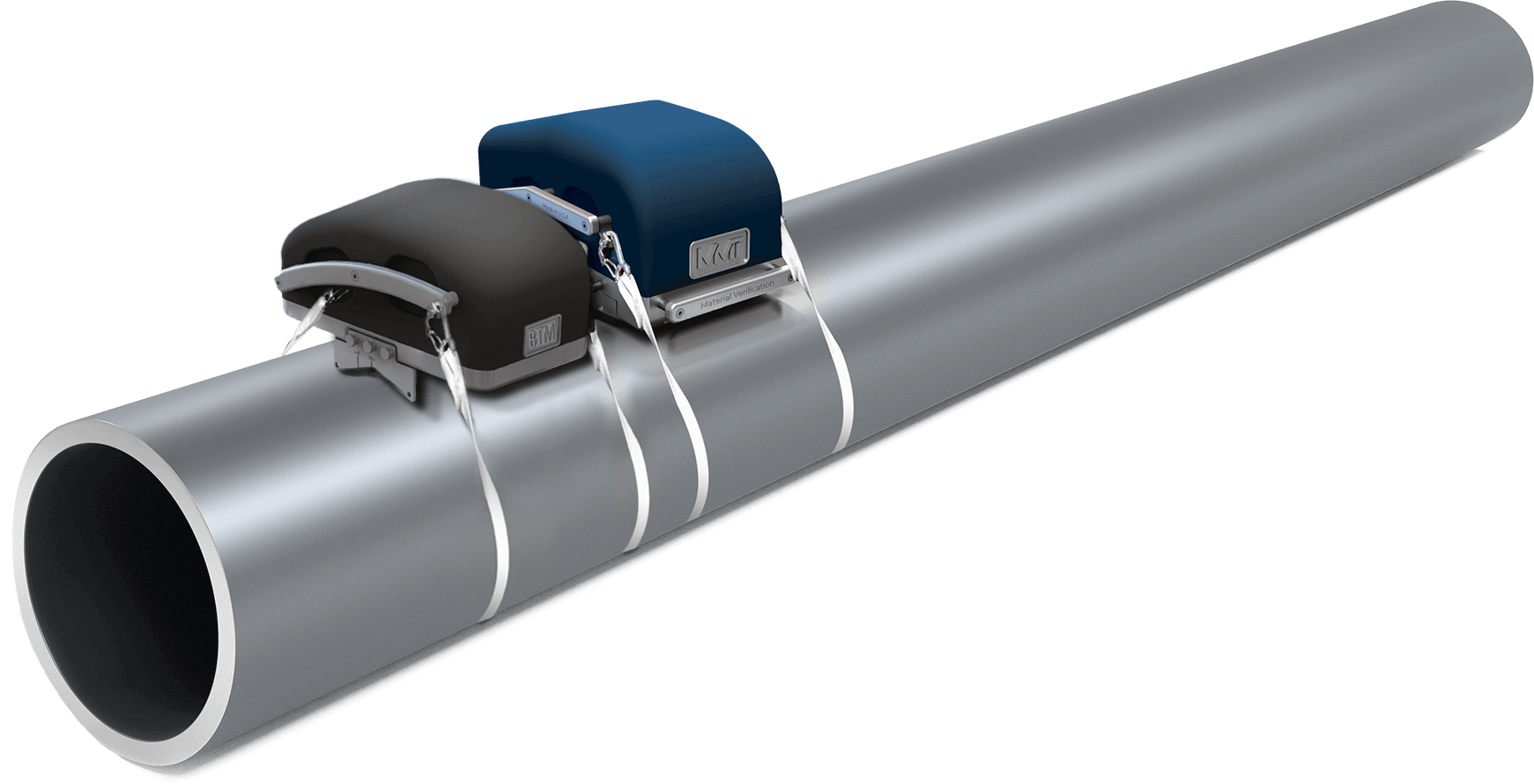

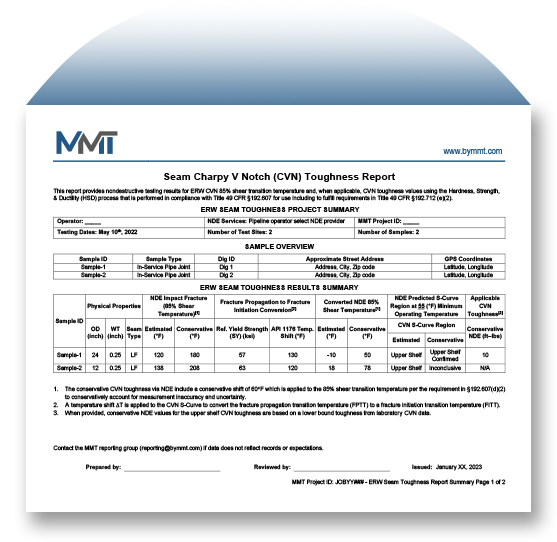

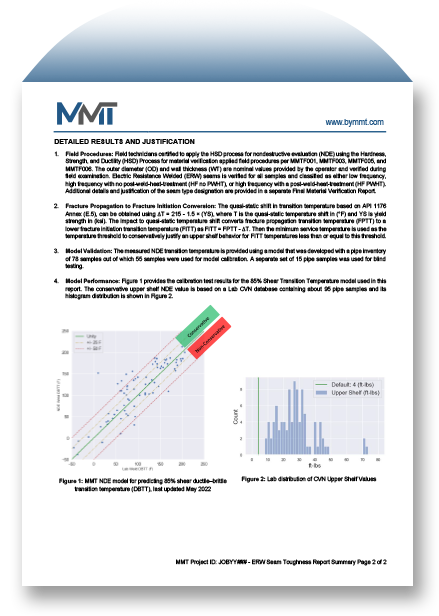

Quantify the durability of pipelines and other infrastructures with nondestructive laboratory-quality-strength metal and toughness properties without service interruption. Instantaneous reporting enables data-driven decisions to ensure regulatory compliance and safe and sustainable operation.